When selecting materials for outdoor seating subjected to vacuum chamber testing, durability and resistance to extreme conditions are paramount. The best materials must withstand temperature fluctuations, UV exposure, and mechanical stress while maintaining structural integrity.

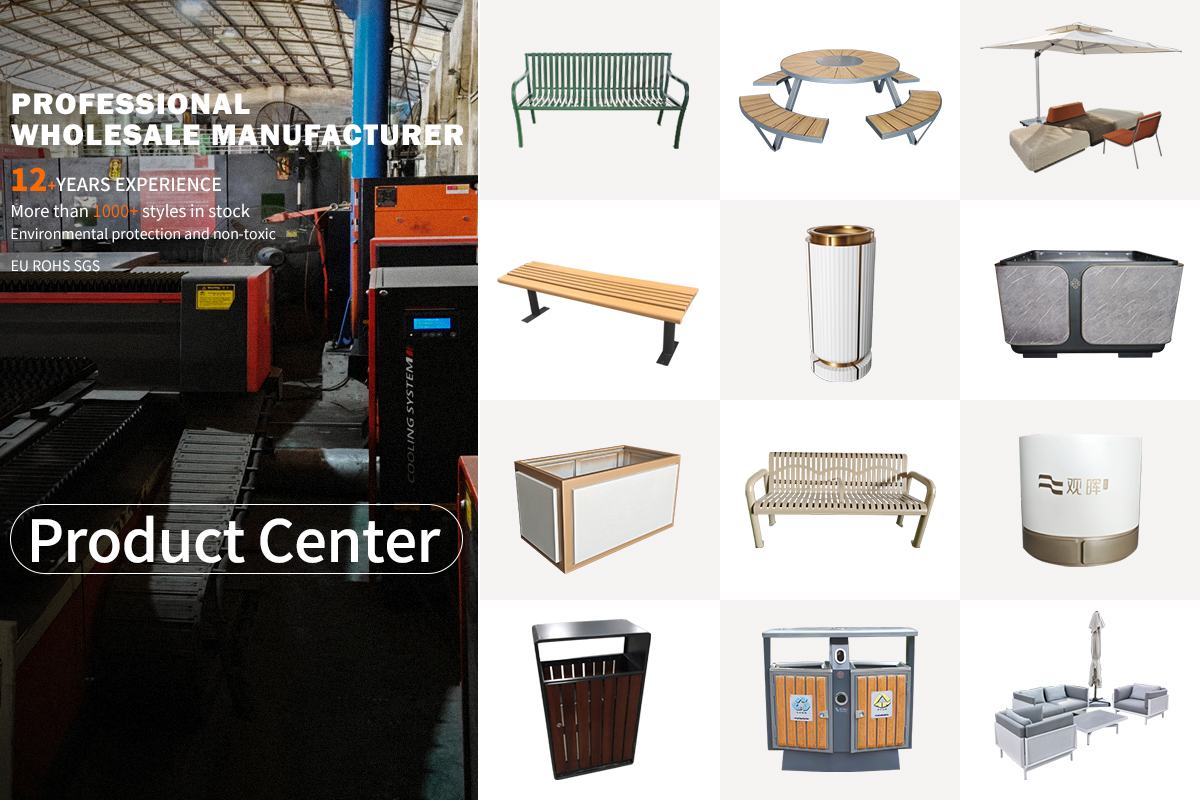

1. Stainless Steel: Known for its corrosion resistance and strength, stainless steel is ideal for vacuum chamber testing. It performs well under high pressure and temperature variations, making it a top choice for outdoor furniture frames.

2. Marine-Grade Aluminum: Lightweight yet robust, marine-grade aluminum resists rust and degradation. Its ability to endure harsh environments makes it suitable for outdoor seating exposed to vacuum testing.

3. High-Density Polyethylene (HDPE): This plastic is UV-resistant, waterproof, and highly durable. HDPE retains its shape and color even after prolonged exposure to vacuum conditions, making it perfect for seating surfaces.

4. Powder-Coated Metals: Metals with powder coatings offer extra protection against scratches and corrosion. The coating ensures longevity, even when tested in vacuum chambers simulating extreme outdoor conditions.

5. Teak Wood: Naturally resistant to moisture and pests, teak is a premium choice for outdoor seating. Its dense grain structure holds up well in vacuum testing, though it requires periodic maintenance.

For optimal performance, combining these materials—such as stainless steel frames with HDPE seating—can enhance durability and comfort. Always prioritize materials tested for vacuum chamber conditions to ensure long-term reliability in outdoor settings.